|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance for Windows |

|

| EZ Maintenance™ is also

available as a Windows's

program for the user seeking

a flat priced maintenance

software solution.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ WEB |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

|

Previous

Section:

Entering

and Viewing Equipment Entering

and Viewing Equipment |

Next

Section:

Maintenance

Due Reports |

|

/video/

|

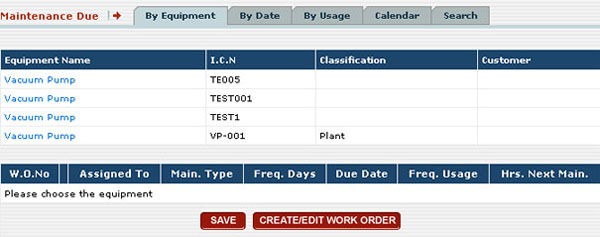

Maintenance

Due

Being able to quickly and easily determine which

preventive maintenance is due and overdue is one of the most important

issues in tracking and controlling preventive maintenance. A complete

schedule of preventive maintenance, for any time period, can be pulled

using EZ Maintenance Web equipment maintenance software. A user can easily

view Maintenance

Due schedules By Equipment, By Date or By Usage.

Clicking on "Maintenance Due" brings

you to this screen, which defaults to displaying equipment by name.

|

Maintenance

Due Sorted By Equipment lists the equipment to

be maintained, and the preventive maintenance due for each equipment

unit. For any Equipment Name selected, you will see a

list of all its pending preventive maintenance. Projected maintenance

due and open Work Orders are viewed here.

Search functions

assist in quickly finding equipment from the list. Clicking on "Search"

brings you to a page with a wide variety of possible search criteria.

Quick Search You can utilize the "Quick

Search" functions on the right hand side of the screen to search for

equipment by work order number, internal control number, serial number. You

can even further refine your results by displaying the results by selecting

to view equipment that is Due Today, Due Previous, or all Maintenance Due

equipment.

Scan a Barcode to Locate

Select the Barcode scan format, then scan the equipment

Barcode, and click Locate. The particular equipment piece

you've scanned will be displayed.

Create/Edit Work Order

Create or edit a Work Order for a preventive maintenance event by

first selecting the event from the list, then

clicking the Create/Edit Work Order button. A preventive maintenance

Work Order is then created and a Work Order Number is

assigned automatically.

Assign Work Orders

Clicking on a piece of equipment displays the previously created work orders

in the bottom half of the screen. You can assign these work orders to

individuals from the drop-down list provided.

Calendar creates

a visual agenda of preventive maintenance events, which are past

due, due today, this week, this month, etc., by selecting

the specific date range you wish to view.

Next Due Date You can see when the next

maintenance due event is scheduled for a particular piece of equipment by

selecting it. In the bottom half of the screen, you will see the list of

open work orders. The far right column is labeled for the next maintenance

due event.

|

| Creating Work Orders |

Notes

& Exceptions fields allow the supervisor to

enter notes as to what was done, or if there were any

variances. Both fields accept a great deal of typed information

for precise note sharing. Notes

& Exceptions fields allow the supervisor to

enter notes as to what was done, or if there were any

variances. Both fields accept a great deal of typed information

for precise note sharing.

Performed By establishes

accountability for the equipment's preventive maintenance history.

Approved By Only

a supervisor with the proper password may sign off or

close a Work Order.

Assigned To allows a manager to assign

the

work order to a specific employee.

Labor Hours, Materials Cost

& Equipment Down Time are entered by the supervisor

closing out the Work Order.

Materials, Operations, Parts

are automatically entered based on set up of the Maintenance

Profile.

|

| Click

here to view an actual Work Order |

Previous

Section:

Entering

and Viewing Equipment Entering

and Viewing Equipment |

Next

Section:

Maintenance

Due Reports |

|

|

|

|

|